Royal Oak, MI — The auto industry is about to take spatial computing to the next level.

That’s the firm belief of the folks at Paris-based industrial-applications provider Dassault Systèmes, which in February announced a deal with Apple to integrate its 3DLive software with the tech company’s Apple Vision Pro high-powered headset computers to enable engineers to do their work in an immersive 3D environment.

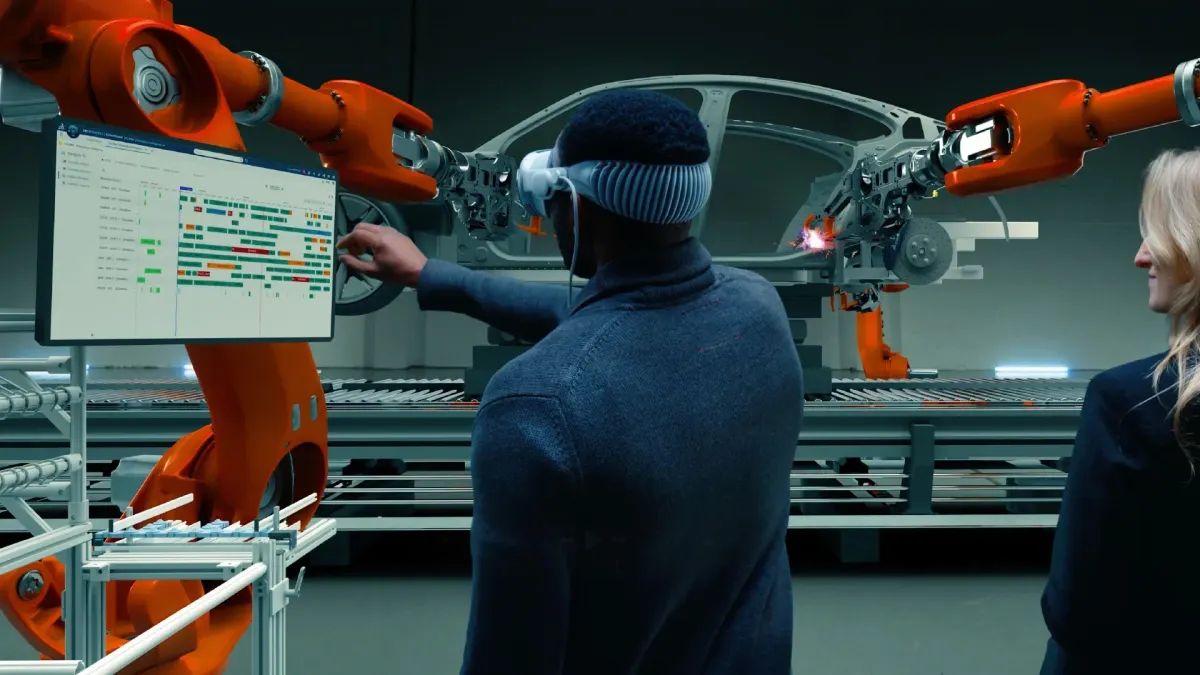

Spatial computing — and potentially the 3DLive application, as demonstrated here at Dassault’s Detroit-area office — could be the next big step toward speeding up product development, allowing engineers more opportunity to innovate in their designs, optimize manufacturing and better ensure quality of the finished vehicle.

With the advent of spatial computing, the industry is moving beyond the concept of the Digital Twin, where a 3D rendering of a vehicle is created using computer-aided engineering, to that of the Virtual Twin, an immersible 3D representation that is more precise and versatile.

“One of the limitations on innovation (is) how well you can accurately represent the ideas you want to make,” said Tom Acland, CEO of Dassault’s 3DEXCITE software suite and leader of the company’s collaboration with Apple. “With a Digital Twin, it’s a flat screen that is representing something in 3D. So it’s not exactly ideal. Although it seems realistic, the more realistic the rendering is, the more disconnected it often is to the real thing.

“That’s why we were so excited when Apple came out with this type of (spatial) computer,” he added, citing the technology’s heightened precision. “(And) it allows you to interact with your virtual ideas just using your hands, your eyes and your voice.”

Key to the 3DLive app, and what executives believe is Dassault’s competitive advantage over other platforms, including those that also work with Apple’s technology, is its inclusion into the company’s 3DEXCITE software suite that offers real-time, end to end product-development capability, from initial designs all the way through manufacturing and beyond.

The advantage of using a design tool such as 3DEXCITE is the speed to which engineering changes can be made and communicated throughout the product-development chain, Dassault officials said. With 3DEXCITE, modifications occur in real time for everyone working along the daisy chain of product development. A tweak made by one engineer is immediately flagged for others who can quickly determine how that may impact their portion of the design.

Contrast that with more conventional CAD technology, with which engineers must pass files along from one department to another, upload them into their systems and run new simulations before passing those files back. That current, more-siloed, approach to product development eats up time and means changes that impact the vehicle or component downstream can be missed if protocols aren’t followed to the letter.

“The time it saves when all (the data) collects together (automatically) is the real value of the platform,” Klaus Kung, director-transportation and mobility industry, said of 3DEXCITE. “It’s the sharing of output in the current state of what has been done here to the guys over there. That is where the companies are gaining the most in time but also in innovation and in reducing mistakes.”

The benefit is easily apparent in the use of product-development tool in the world of Formula 1 racing, where teams must quickly make hundreds of tiny changes to optimize their vehicle chassis for the next race.

With the real-time capability of 3DEXCITE, “as an F1 team is getting feedback from a racetrack…they can say, ‘What if we stiffen up (the suspension) a bit, what would that do for us going around that corner?’” said Bill DeVries, vice president North America brands and workforce of the future. “In a (conventional) digital world, they’d be taking a model and (running) a simulation…and go through that (time-consuming) process. We’re doing it live, in real time and engineers are getting real-time feedback of what that (change) is going to do.

“That’s what we’re trying to enable in the innovation process with all of our customers.”

3DLive adds another dimension to the Dassault platform, creating a virtual copy that allows engineers to view every detail of a complete vehicle at scale, disassemble and examine parts virtually with their hands and validate a manufacturing process. And because it is part of 3DXCITE, engineers can share the virtual room simultaneously with those halfway around the world to make and test changes in real time and validate the results.

Biometric authorization that uses a headset wearer’s eyes for authentication ensures security for the data.

“This is interesting for us and our clients, because some of the information…is highly sensitive,” Acland said. “It’s their core value, it’s their IP. So to be able to deliver experiences that are literally for your eyes only is transformational.”

In a demonstration here, Dassault showed off the software’s ability to train workers, solve manufacturing hurdles and tweak vehicle designs. After a short setup to calibrate the wearer’s vision to the headset, operation is simple and intuitive, responding to eye movements and hand gestures, and the virtual renderings are crisp, colorful and realistic.

In one demo, a fullsize mock Formula 1 vehicle filled the floor, where headset wearers could perform full walk-arounds examining such things as aerodynamic air flows or disassembling a front axle to view individual parts.

In another, a complete factory floor is rendered, enabling engineers to vet production processes and provide training for future line workers.

“Training is probably the No.1 ask we have from companies,” said Kung, noting setting up training is relatively easy because data already created by the engineers can be used to devise such programs.

Legacy companies are under the gun to speed product development in order to compete with upstart automakers, in some cases capable of engineering a clean-sheet vehicle in as little as 18 months.

“There’s a lot of pressure on how fast they can design a car,” DeVries said of traditional automakers. “(China) has set the bar at an extremely low (timetable). And if traditional OEMs are going to compete, all have to change the way they’re thinking. They can’t continue to operate how they were operating 20 years ago.

“We are the company that’s trying to take the innovation process to the next level.”

It’s still early days for the Apple-compatible 3DLive tool, released in July, but Dassault made a strong pitch for the software to more than 100 automotive customers here in late September.

“The light bulbs that go off for our customers are on how it can impact their manufacturing process, their design process, their innovation process,” DeVries said. “No matter what they’re making…they can see how this can be applied. If a picture’s worth a 1,000 words, what’s a Virtual Twin experience worth? It’s exponentially more.”

Dassault said already half of its automotive customers have decided to move to the core 3DEXCITE real-time engineering platform and more are expected to follow suit later this year.

“We need to shorten development time, otherwise we’ve lost — we’re losing market share, we’re losing competitiveness,” Kung said of traditional OEMs.

A more aggressive shift toward spatial computing may be a logical next step in efforts to turn that tide.

“Using these Virtual Twins in order to power their innovation process — more and more (automakers and suppliers) are moving that way,” said DeVries