Vehicle cost and range limitations discourage today’s U.S. drivers from switching to electric vehicles. While the first point of criticism is gradually disappearing as the quantity of vehicles manufactured increases, ZF already is in the process of extending the range of each charge, while at the same time bringing to market an all-new 8-speed transmission designed for conventional and hybrid-electric vehicles.

Perfectly matched drive components

Vehicle range can of course be increased by installing a bigger battery. However, the consequences are less space for passengers and luggage, greater vehicle weight and higher vehicle cost.

It makes more sense to design all components of the driveline as well as possible and to coordinate them perfectly, which is the approach ZF is taking. By taking this approach, even small optimizations can bring about a noticeable overall increase in efficiency. For example, an inverter with power electronics that is well matched to the drive system contributes to optimum use of the available energy.

This is obtained through the adoption of more advanced technologies such as permanent-magnet synchronous e-motors or silicon-carbide power modules. These modules provide higher efficiency and lower losses but also higher operating temperature and higher switching frequency, which enable the e-motors to operate at higher efficiency for a significant system benefit.

Multiple benefits thanks to electric motor and transmission

An additional approach to increasing efficiency in e-mobility builds on ZF’s expertise in transmission technology: ZF developers have equipped a new, compact electric car drive with a 2-speed transmission.

The new 2-speed electric drive with a maximum output of 180 hp (140 kW) allows a passenger car to be driven at higher speeds with much greater energy efficiency than is the case with conventional electric vehicles.

At the same time, the electric vehicle does not lose traction at lower speeds. Together with the integrated power electronics, the electric drive with a shift element ensures an increase in range of up to 5%.

This driveline opens various application options for automakers. For example, they can offer vehicles featuring an extended range with the same battery size, counteracting the primary concern of many customers.

The efficiency gain also allows the drive to be combined with a smaller battery, saving money, installation space and weight, which benefits price-sensitive subcompact and city cars. The modular 2-speed drive is also aimed at manufacturers that focus on performance.

Until now, electric drives were associated with a choice between a high starting torque or a high top speed. Together with a powerful electric motor of up to 335 hp (250 kW), the new drive concept provides enough power to ensure that drivers of sporty or heavy-duty vehicles do not have to make compromises when starting off or driving at top speed.

Silicon-carbide power modules are among many efficiency enhancing technologies available.

Transitional technology with power and performance

But not all consumers are ready to adopt pure EVs. According to our forecasts, at least 70% of all new cars still will have a combustion engine in 2030. For this transition period, full-hybrid (including plug-ins) and mild (48V) models will be part of the required mix and will significantly lower vehicle carbon dioxide emissions.

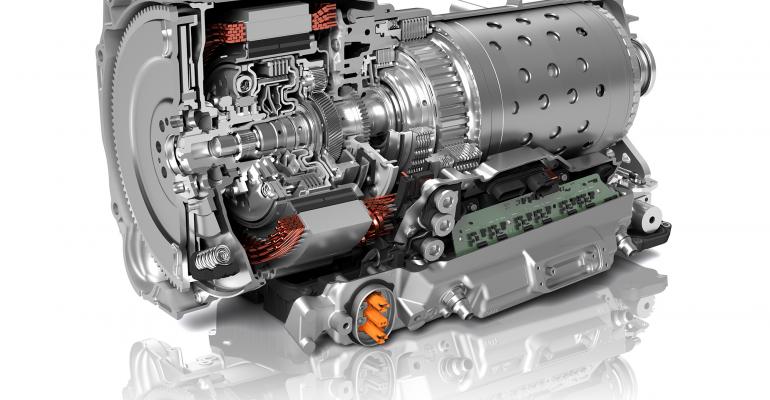

ZF’s all-new 8-speed automatic transmission for conventional and hybrid vehicles, unveiled earlier this year, was specifically developed for both conventional and various levels of hybrid operation.

When equipped with a wide range of optional electric motors from 32 hp (24 kW) to 214 hp (160 kW), and torque levels up to 332 lb. ft. (450 Nm) without activating the internal combustion engine, the system allows for swift passing, even when in e-mode.

The transmission’s flexible and modular design enables conventional, mild, full and plug-in hybrid variants depending on customer demand. While plug-in hybrid vehicles are more complex EVs, they provide consumers a solution to range anxiety on longer distance travel, while allowing full electric driving in zero emissions zones or during daily commutes.

The transmission’s flexible and modular design enables conventional, mild, full and plug-in hybrid variants depending on customer demand. While plug-in hybrid vehicles are more complex EVs, they provide consumers a solution to range anxiety on longer distance travel, while allowing full electric driving in zero emissions zones or during daily commutes.

Prepared for the unpredictable future

These and other EV and hybrid technologies are important because the future of electric and/or hybrid vehicles is real, it’s not just something we talk about or may see in the future. LMC Automotive forecasts that in 2025 there will be 428 battery-electric models in the global market; in 2019, there were 144. Automakers and government regulators are confirming a serious focus on these alternative powertrains, but projections vary.

With no crystal ball in hand, ZF is well positioned with products, people and production locations to successfully meet these challenges head on.

Jörg Trampler (pictured above, left) is Head of Engineering Center North America, Car Powertrain Technology, ZF Friedrichshafen.