General Motors says it will slash the number of vehicle and engine architectures over the next decade, while drastically cutting the amount of effort it takes to produce a new vehicle over the near term, as it looks to improve its bottom line and boost its global-market standing.

Mary Barra, senior vice president-global product development, says key to the cost-improvement goals will be to smooth out product-development investment plans, eliminating the hills and valleys caused when GM started and stopped vehicle programs due to swings in the market and its financial troubles.

![<link rel="stylesheet" href="http://subscribers.wardsauto.com/galleries/files/lightbox.css" type="text/css" media="screen" />

<script src="http://subscribers.wardsauto.com/galleries/files/prototype.js" type="text/javascript"></script>

<script src="http://subscribers.wardsauto.com/galleries/files/scriptaculous.js?load=effects" type="text/javascript"></script>

<script src="http://subscribers.wardsauto.com/galleries/files/lightbox.js" type="text/javascript"></script>

<p><a href="http://subscribers.wardsauto.com/galleries/2011/GMchart-gallery.jpg" rel="lightbox[plants]" title=" ">View Photo Larger</a></p>

<a href="http://subscribers.wardsauto.com/galleries/2011/GMchart-gallery.jpg" rel="lightbox[plants]" title=" GM to trim global vehicle architectures by half.

"></a>](http://subscribers.wardsauto.com/images/2011/08/GM-chart.jpg)

“Start/stop is a great technology for fuel efficiency, but it’s a horrible way to run the product-development business,” she says as part of a presentation to financial analysts by top GM executives on the auto maker’s plans for the next three to five years.

“Straight-line investment is critically important. It allows us to have better quality and productivity and get to the market faster.”

Barra points to GM’s Lambda-based midsized cross/utility vehicles (GMC Acadia, Buick Enclave, Chevrolet Traverse), saying those models could have been on the market 18 months earlier had it not been for GM’s financial problems that shut down the development program at times.

“It creates frustration (for engineers),” she says, adding stopping a program midstream also puts GM well behind the competition in bringing innovations to market.

CEO Dan Akerson says the product-development hiccups cost GM $1 billion annually in the past.

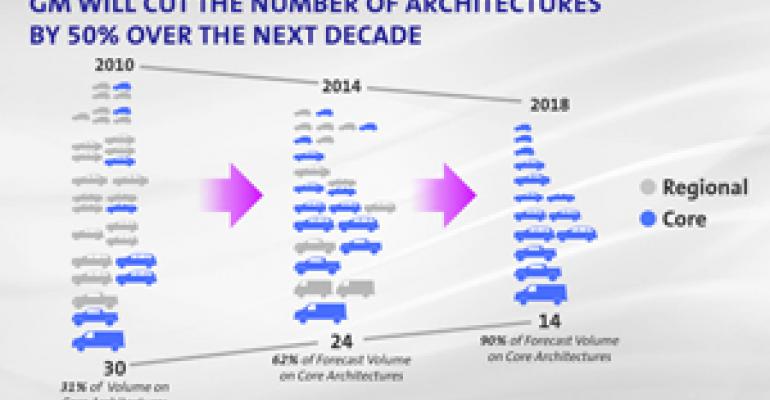

To improve efficiency, GM will trim its global vehicle architectures from 24 in 2010 to 14 in 2018.

It also will better utilize those platforms. Last year, those 24 global architectures covered 31% of GM’s vehicle volume. The 14 remaining platforms will cover 90% of its volume in 2018.

Engine architectures will be slashed from about 20 now to 10 over the next decade. Barra points to a new family of 1L-1.5L gasoline powerplants that will replace three engine families around the world as one example of consolidation.

GM also has identified ways to improve product-development efficiency more immediately. In benchmarking its operations, it found too many people focused on non-program engineering – about 25% more than at other auto makers.

“We think we can get them working on product programs and get better products to market more quickly,” Barra says.

She is targeting an overall 40% reduction in the number of person/months needed to develop an all-new vehicle architecture, and about a 30% improvement in engineering carryover platforms.

“We’re talking weeks and months to see these types of benefits, as opposed to accomplishing that over several years,” Barra says.