Noise, vibration and harshness are key factors in how people assess the quality of a vehicle. While low NVH levels are essential, so is the steering feel, which can affect the steering components used.

Due to cost-reduction and lightweighting market trends, the most common type of power steering for A- and B-segment vehicles is column-mounted electronic power steering (C-EPS).

Its cost advantages are derived from the electric motor sitting behind the firewall, much closer to the steering wheel and vehicle operator. The motor must withstand lower temperatures. It can be manufactured more economically and is significantly lighter compared with hydraulic power steering, while assembly for the OEM is much easier.

Despite advantages, this solution can sometimes cause the steering wheel to buzz or vibrate.

How can NVH issues be tackled cost-effectively without annoying steering-wheel buzz?

The answer comes from understanding how C-EPS works. Its main function is to reduce the effort required to turn the steering wheel. This happens by creating the right amount of torque dependent on driver input – is the driver making a sudden evasive maneuver or gradually changing direction on a bending highway? Therefore, the input torque must be measured.

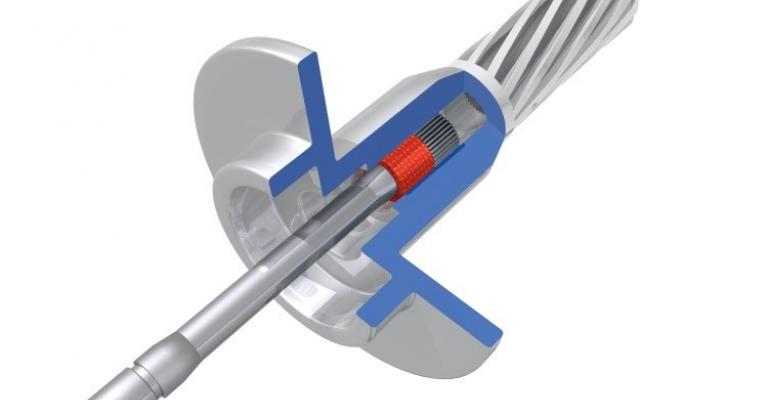

The steering column ahead of the motor is split into two sections, joined by a smaller, less stiff shaft known as a quill shaft, or torsion bar. While the upper column is turned by the driver, the lower column resists the motion due to friction between the tires and the road surface. The resulting displacement is measured and used to calculate the correct amount of torque the electric motor should generate.

The upper and lower part of the column can slide over each other because they are separated by a bearing (see photo below). This is typically a needle bearing, which creates metal-to-metal contact and can generate the buzzing feel in the steering wheel and negatively impact brand perceptions.

The metal-to-metal contact also can cause brinelling of the shaft, which can result in inaccurate torque measurements. To avoid this, the shaft must be heat-treated to increase hardness, adding cost.

Key to improving NVH perception and the overall driving experience is eradication of the metal-to-metal contact, for example by using composite bearings. These comprise a sliding layer made of polytetrafluoroethylene (PTFE) or a similar polymer.

This PTFE compound removes the brinelling problem, eliminates the need for costly hardening and provides damping to the system. It also reduces the buzzing feel from the steering wheel, improving quality perception.

Composite bearings have other advantages, from their ability to compensate for mating component tolerances to removing the need for a costly precision ground surface on the shaft.

Testing noise levels is essential to proving this concept to automakers. For power steering systems, the best environment for effective noise testing is an anechoic chamber. Over several years, suppliers such as Saint-Gobain in Bristol, U.K, have invested in this sophisticated approach. In these test chambers, background noise is negligible.

Testing noise levels is essential to proving this concept to automakers. For power steering systems, the best environment for effective noise testing is an anechoic chamber. Over several years, suppliers such as Saint-Gobain in Bristol, U.K, have invested in this sophisticated approach. In these test chambers, background noise is negligible.

Figure 3 (see below) illustrates the results of a noise test for the C-EPS system. A PTFE-based composite bearing was tested against a needle bearing. The result: a clear reduction of sound pressure level of gear teeth chatter during a rotational excitation of the steering column (more specifically, an overall reduction in noise of almost 8 dB(A)).

This shows that PTFE-based composite bearings – a drop-in replacement for a needle bearing without the need to redesign the system – can reduce noise and enable a low-cost solution such as C-EPS to exhibit good NVH properties and improve the end-user’s perception of quality of the whole vehicle, thanks to a comfortable driving experience.

Alfred Lethbridge PhD (above, left) is an NVH engineer at Saint-Gobain and specializes in optical and oscillations in resonant systems.