DETROIT – Diana Mannino has spent about 30 years in the auto industry, including an early job at the General Motors Technology Center in her hometown of Warren, MI, a Motor City suburb.

In January, she became president of HBPO North America, a unit of Germany-based HBPO that produces front-end vehicle modules. She joined the supplier in 2015 as a financial director.

The company is a joint venture involving suppliers Mahle Behr, Hella and Plastic Omnium. The company produces about 5 million front-end modules annually.

HBPO operates 25 manufacturing facilities and eight technical centers around the world. An engineering center and the North American headquarters are in Troy, MI. Plants in North America consist of one in Canada and three in Mexico, where two more will open this year.

HBPO was among the exhibitors at Automobili-D, an event intended to highlight new and future automotive technology. It was held in conjunction with the North American International Auto Show here.

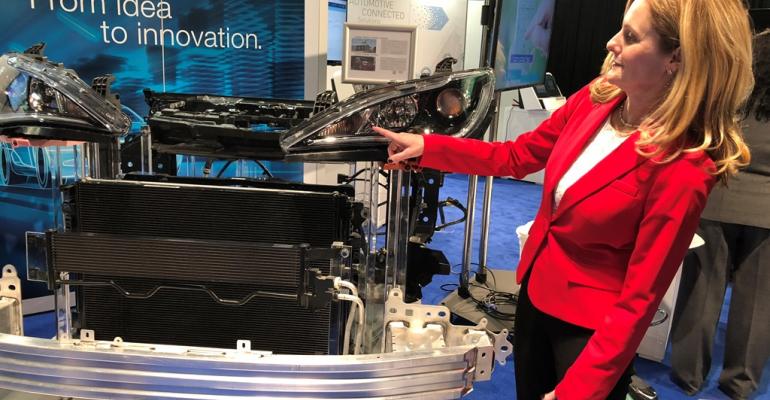

The HBPO display includes a model of the Chrysler Pacifica’s HBPO-built front end. Key components include an engine cooling system, crash bumper and headlamps. Front end modules typically include wire harnesses, horns, sensors and, increasingly, safety components.

WardsAuto spoke with Mannino at HBPO’s Automobili-D exhibit.

WardsAuto: Modules are a big deal these days for auto suppliers. Many of them have gone from supplying parts to components to full modules. Describe that evolution.

Mannino: More and more, the OEMs are looking for savings in floor space with shorter assembly lines of their own. They are looking for companies such as ours to design and engineer the front ends, do the acquisition of materials, produce the module and ship just-in-sequence. There’s a working-capital advantage in that and the advantage of dealing with just one Tier 1 supplier vs. many suppliers.

WardsAuto: What was the turning point in module assemblies?

Mannino: Module assembly has been around for a long time now. But the modules are getting more complex. More parts are being added. Content overall is increasing. The other thing going on is the OEM push for us to design lighter-weight technologies, yet produce front ends with the necessary stiffness and rigidity for passing crash tests.

The other thing we’re focused on in the market right now is active grille-shutter technology. That involves aerodynamic management.

WardsAuto: So if you don’t need the air intake, it shuts off automatically?

Mannino: Yes. When the vehicle gets up to a high rate of speed, the grille shuts and you get a better aerodynamic airflow, reducing CO2 emissions and getting better fuel economy. We’re seeing higher take rates of that technology.

WardsAuto: Go back a bit to the lightweighting and the ability to pass a crash test. The front end can be a vulnerable part of a vehicle in a traffic accident.

Mannino: It is the ability to merge plastic technologies with steel or aluminum. It involves coming up with designs and different material mixtures and working with the OEM to achieve the lightest-weight-possible front end that’s able to meet the ever-increasing safety and crash-test requirements.

WardsAuto: Just to clarify, when you talk of mixing plastics and metals you’re talking about adhering those things, not creating some sort of alloy?

Mannino: Right. And processes such as injection molding. It’s a combination of the metal and plastic technology coming together.

WardsAuto: What brings you to AutoMobili-D?

Mannino: We’re showcasing a couple of modules with which we worked closely with an OEM. For instance, with the Chrysler Pacifica module on display here, we were able to achieve a 25% weight reduction through design, development and materials.

We recently returned from CES in Las Vegas. We go there trying to understand what the front ends of these new electric vehicles look like, and what do we need to do to get out in front of it.

WardsAuto: Are you also looking at what the front of impending autonomous vehicles will look like.

Mannino: Exactly. That’s what I mean, electric and autonomous both.

WardsAuto: Will or do they look real different?

Mannino: Not necessarily. We’re seeing a lot of different shapes and a lot of LED technology on the front end. (An emerging technology is) integrated headlamps. It’s a different construction we’ll have to adapt to. Quickly.