Nissan’s world-first variable-compression-ratio 2.0L turbocharged 4-cyl. made quite a splash when it was introduced in the ’19 Infiniti QX50.

Designated KR20DDET, the powerplant received good reviews from WardsAuto Editor Bob Gritzinger last November following a test drive at Nissan’s Desert Proving Grounds.

But this remarkable engine also will be available in the ’19 Nissan Altima (SR and Platinum FWD) grades when the all-new midsize sedan arrives this fall.

Clearly, it’s destined to be much more than just a high-tech engine for Infiniti-branded vehicles. It also is expected to migrate into a variety of Nissan products, though mostly upper-level models due to its higher cost.

Meanwhile, Nissan will offer the new PR25DD 2.5L I-4 as the standard engine with lower trim levels.

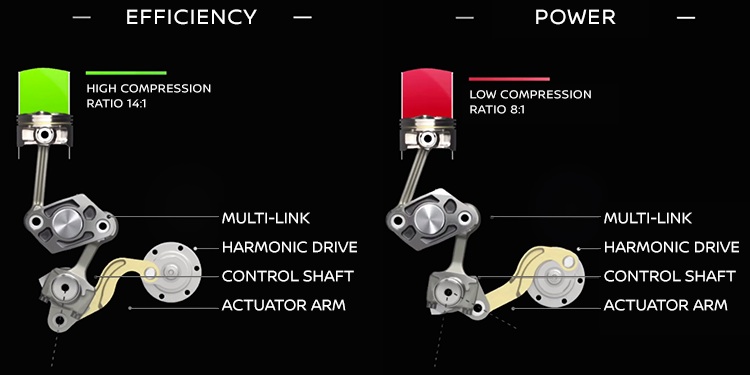

The VC engine has been in development more than 20 years. Its world-first multi-link connecting-rod system, powered by an electric motor through a unique “harmonic drive” reduction gear, continuously varies piston stroke from 88.9 mm to 90.1 mm and displacement from 1,990 to 1,997 cc and compression ratio from 8:1 (for high performance) to 14:1 (for high efficiency).

Tested against comparable rivals, it provides both a roughly 1-mpg fuel economy benefit and a 1-second 0-60 mph (0-97 km/h) acceleration gain, according to Nissan.

While all-wheel drive will be offered with the standard engine (the only segment competitor with AWD is Subaru) it will not – at least initially – be available with the VC Turbo.

While the QX50’s VC-Turbo pumps out 268 hp and 280 lb.-ft. (380 Nm) of torque on premium fuel, the Altima version delivers a more modest 248 hp and 273 lb.-ft. (370 Nm) operating very happily on (87 octane) regular gas. That is 22 fewer horses but 22 lb.-ft. (30 Nm) more torque than the 3.5L V-6 it very capably replaces.

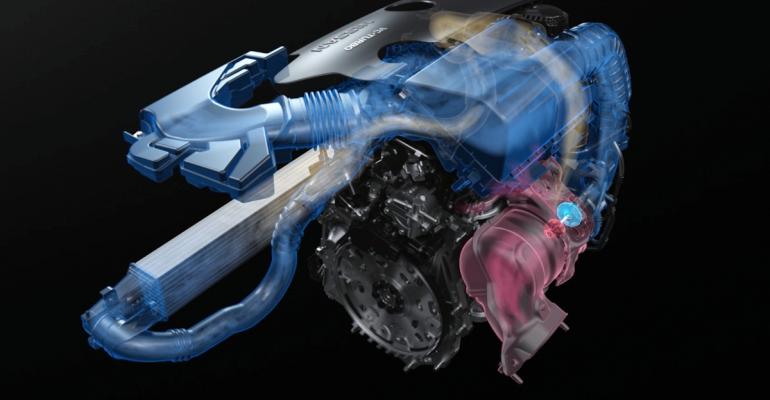

It switches between multi-point and direct fuel injection, the former for more complete low-load combustion, the latter for performance, efficiency and knock avoidance at high compression ratios. Both work together at high loads.

Electronic variable valve timing enables the engine to switch between Atkinson and regular combustion cycles to optimize performance and efficiency throughout the compression-ratio range.

A single-scroll Honeywell turbocharger driven through an integrated exhaust manifold provides near-immediate accelerator response.

While the added variable compression hardware makes it some 22 lb. (10 kg) heavier than competitive 2.0L turbo 4-cyl. engines, it partially compensates by eliminating the need for balance shafts.

Low-friction bore coating, closer-to-vertical piston strokes, a 2-stage variable displacement oil pump and other advanced measures help it deliver outstanding 40% thermal efficiency.

The world-first multi-link connecting-rod system, powered by an electric motor through a unique “harmonic drive” reduction gear, continuously varies piston stroke from 88.9 mm to 90.1 mm.

Somewhat surprisingly, the VC system is designed primarily to optimize performance (and therefore customer satisfaction) rather than efficiency.

Nissan’s Base PR25DD 2.5L 4-cyl. is not an update of Nissan’s widely used current 2.5L I-4, 95% of its parts are new.

It delivers 188 hp and 180 lb.-ft. (244 Nm) of torque, up 9 hp and 3 lb.-ft. (4 Nm) from the outgoing 2.5L base engine, along with improved fuel economy.

Its world-first thermal-insulated resin intake port uses an air layer to cool intake air and its overall NVH is substantially improved, partly because its lower profile, thanks to a “reverse” cylinder head with integrated exhaust manifold and low engine mounting in the new platform, helps reduce vibration noise by five decibels.

The integrated exhaust manifold improves both packaging and catalyst heating.

New direct fuel injection enables higher (12:1) compression for improved efficiency.

It also uses electronic valve-timing control (e-VTC) and variable-tumble-control intake valves.

The engine also features cooled external exhaust-gas recirculation; mirror-bore cylinder coating, which reduces friction, and a variable-displacement oil pump.